Flexibility matters…

We cover a range of pipeline diameters with our fleet of 30 microtunnelling machines.

With over 30 years of trenchless construction experience, Rob Carr has used trenchless techniques to successfully construct many tunnels for pipeline infrastructure beneath major roads, railways, runways, waterways and environmentally sensitive areas. Our capability ranges from regional works right through to dense metropolitan CBD environments.

We utilise 2 specific techniques to undertake our trenchless construction, a) slurry pressure balanced microtunnelling and b) pilot auger soil displacement tunnelling. Either is used to address access challenges, minimal site footprints, varying ground conditions, urban disruption, distances. Both techniques are used to construct

critical drainage, water or energy utilities infrastructure.

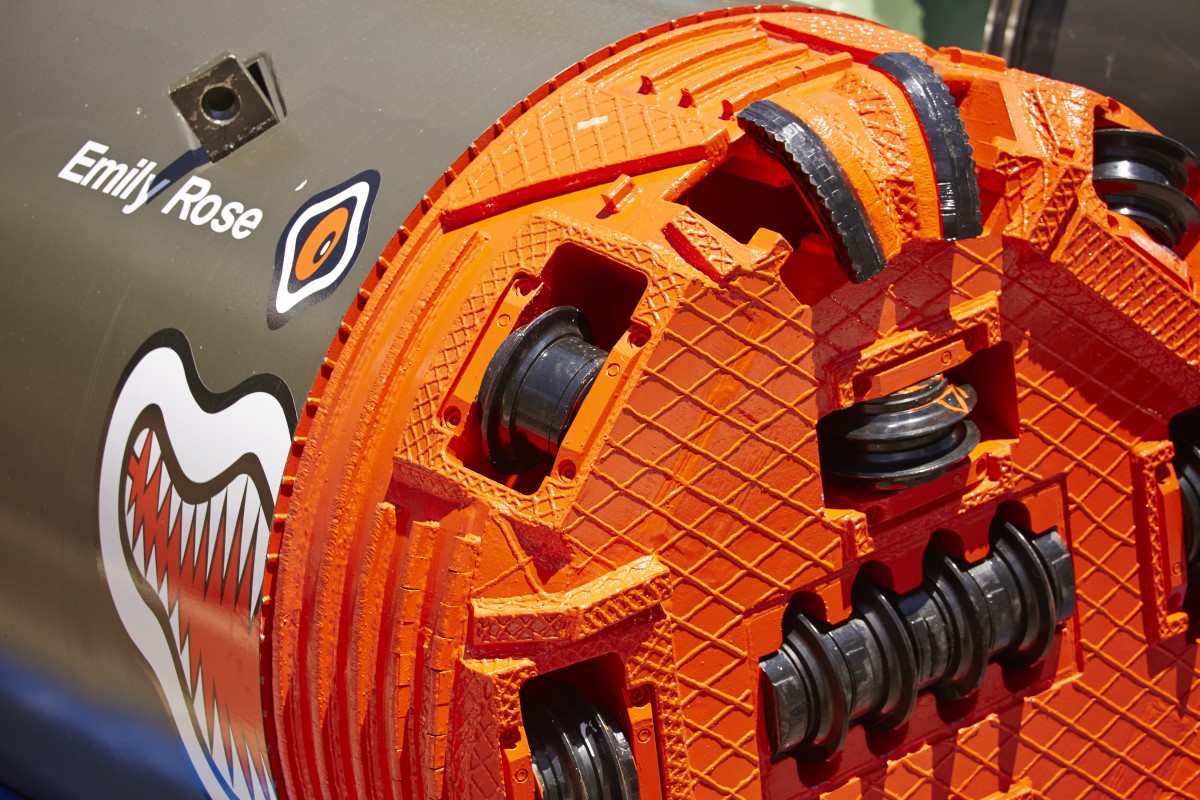

Rob Carr owns a fleet of 30 microtunnelling machines with the largest machine diameter being 2180mm covering all ground conditions. The machines are supported with wide ranging ancillary equipment fleet in the form of control cabins, jacking frames, slurry separation tanks and systems, gantry cranes, power generation and guidance equipment. We typically use Iseki Unclemole and Unclemole Super microtunnelling machines which have a reputation for versatility, efficiency and environmental sustainability.

The company has also recently invested in German Herrenknecht AVN technology to facilitate the growth of the business into larger scale tunnelling projects.

Our capabilities